We produce products that add life to life and structures.

We have more than 90 years of experience in the field of construction chemicals. We offer a comprehensive range of end-to-end solutions for industrial, architectural, and general construction. We are into specialised construction such as heritage structures, places of worship, power, roads, ports and airports. We add expertise to the repair and rehabilitation industry.

Our competence lies not only in our cutting-edge technology but also in our reach to the vast Indian market through a nationwide network of distributors.

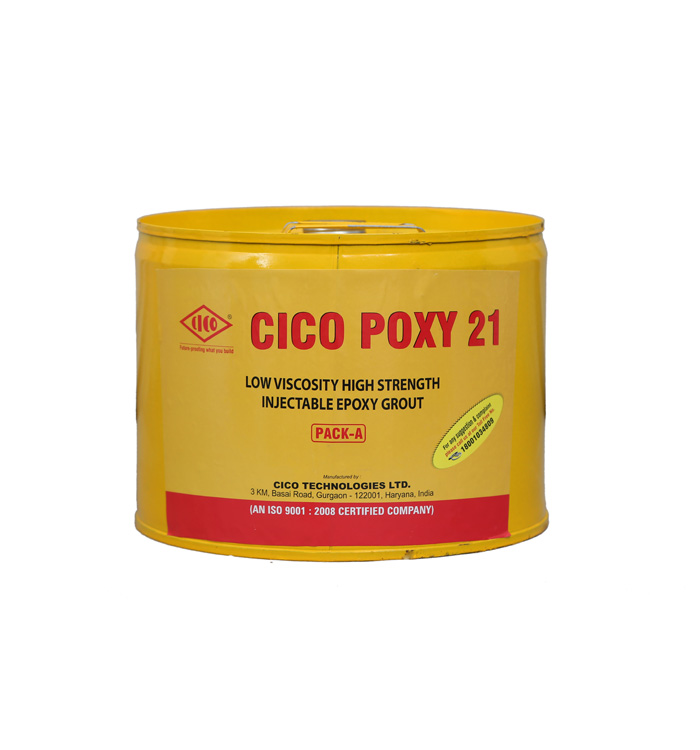

We make the future, safe and secure. We are in the future-proofing business. We manufacture a vast range of construction chemicals and protective coating solutions including water-proofers, concrete admixtures, grout and grouting compound, industrial flooring, epoxy-based products and repair compounds, adhesives and sealants. What does that do?

It lays a strong foundation for an everlasting edifice and enhances its longevity and value. With our products invented at our state-of-the-art research laboratories, we have added life to several buildings and projects that are an integral part of this country’s life.

We have innovative and iconic products. We have scores of products in various categories such as various water-proofing, concrete admixture, grouting, industrial flooring, adhesives, sealants, repair compounds and several others. Many are market leaders. Most are market readers. Here are some of the categories we work in and our market-leading brands:

Our sustainable success is a result of collective and collected wisdom. We do different things. And we do them differently. We do it by harnessing the best-in-class technology and manufacturing processes to come up with products that are safe and in keeping with the changing demands of the construction industry. We do not merely embrace innovation. We accelerate it.

And as we innovate, we collaborate. Some of the finest names in the world are a part of our world.We have been, both, rewarded and awarded by the best. We have both history and geography.

We believe a company is the company it keeps. To that end, we are in great company. From homes and important commercial buildings to heritage structures and historical monuments to nuclear and thermal power generation projects and surface transport infrastructure to airports, across the country, there is hardly an area where our products haven’t left their mark. For life. Here is a truncated list of projects where CICO’s products have been used extensively.